PCB

PCB

Blog Article

The Hidden Technology Behind Electronics: A Deep Dive into Printed Circuit Boards (PCBs)

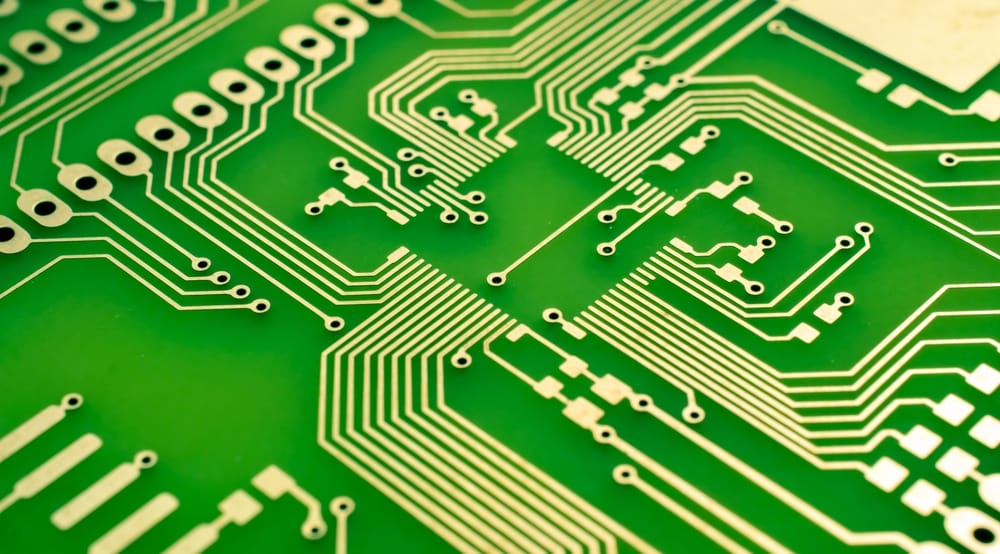

In our technology-driven world, we often marvel at the sleek design and powerful capabilities of our electronic devices. However, behind the scenes, a quiet hero plays a vital role in making these wonders possible: the Printed Circuit Board (PCB). These unassuming boards are the unsung heroes that underpin the functionality of countless electronic devices. In this article, we will explore the world of PCBs, shedding light on their importance, construction, and diverse applications. Take a closer look at microwave PCB.

The Significance of PCBs

A Printed Circuit Board, commonly referred to as a PCB, is a flat, rigid, or flexible board made from non-conductive materials, typically fiberglass or epoxy resin. PCBs serve as the foundation for connecting and supporting electronic components, enabling the creation of complex electronic circuits. They are the unsung heroes that ensure electrical connections are made efficiently and reliably, allowing electronic devices to function as intended.

The Role of PCBs in Electronics

Why are PCBs so critical in the world of electronics? Here are several key reasons:

- Reliability: PCBs provide a stable and dependable platform for connecting electronic components. Unlike manual wiring, PCBs reduce the risk of loose connections and short circuits, ensuring consistent and reliable performance.

- Efficiency: PCBs streamline the manufacturing process by eliminating the need for intricate wiring. This simplification reduces manufacturing errors and lowers production costs.

- Space Optimization: PCBs allow for the creation of compact and space-efficient electronic devices, making them an essential component in the design of portable gadgets and miniaturized technology.

The Anatomy of a PCB

To gain a better understanding of PCBs, let's examine their primary components:

- Substrate Material: The base material of a PCB provides mechanical support and electrical insulation. Common substrate materials include fiberglass-reinforced epoxy (FR-4) and polyimide.

- Copper Traces: Thin copper foils are bonded to the substrate material. These copper traces serve as conductive pathways, enabling the flow of electrical signals between components.

- Electronic Components: A diverse array of electronic components, including resistors, capacitors, integrated circuits (ICs), transistors, and connectors, are soldered onto the PCB. These components work together to create electronic circuits and perform specific functions.

- Solder Mask: A layer of solder mask is applied over the PCB's surface. This protective coating shields the copper traces from environmental factors, prevents short circuits, and enhances the overall appearance of the board.

- Silkscreen: The silkscreen layer contains printed labels and markings that provide vital information about component placement, polarity, reference designators, and other essential details.

Types of PCBs

PCBs come in various types, each tailored to specific needs:

- Single-Sided PCBs: These PCBs have copper traces on one side and are suitable for simpler, less complex electronic applications.

- Double-Sided PCBs: Featuring copper traces on both sides interconnected by vias (small holes filled with conductive material), double-sided PCBs are used in more complex electronic systems.

- Multilayer PCBs: Multilayer PCBs consist of multiple substrate layers interconnected with copper traces. They are indispensable in advanced electronics where space constraints and high performance are essential.

- Rigid and Flexible PCBs: While rigid PCBs maintain a fixed shape, flexible PCBs can bend and conform to various shapes. Flexible PCBs are used in applications where form factor flexibility is crucial.

Applications of PCBs

The versatility of PCBs is reflected in their wide-ranging applications across industries:

- Consumer Electronics: PCBs power smartphones, tablets, laptops, televisions, and gaming consoles, making them an integral part of our daily lives.

- Automotive: In vehicles, PCBs control engine management systems, infotainment, and safety features, contributing to the evolution of smart and connected cars.

- Medical Devices: PCBs are vital components in medical equipment such as MRI machines, pacemakers, and diagnostic devices, where precision and reliability are paramount.

- Industrial Control Systems: Industrial machinery, automation systems, and robotics rely on PCBs for efficient control and monitoring, ensuring seamless production processes.

- Aerospace and Defense: PCBs play an integral role in aircraft avionics, missile guidance systems, and communication equipment used in defense applications, where mission-critical reliability is non-negotiable.

Conclusion

Printed Circuit Boards (PCBs) may not be in the spotlight, but they are the unsung heroes that power our increasingly digital world. Their ability to simplify manufacturing, enhance reliability, and enable compact electronics is indispensable. Understanding the significance of PCBs is essential for anyone interested in electronics, as they are the backbone of our modern, technology-driven society. These unassuming boards play a pivotal role in ensuring that our electronic devices function seamlessly, day in and day out, bringing technology to life.

Report this page